Efficient output for existing heat engines is 35...45%.

That is a limit is for traditional technologies.

Are there any possibilities available today to maximize efficiency?

Yes. There are.

«Quanttor technology enables increasing efficiency of the fuel chemical energy conversion. High efficiency is achieved via

How much energy is spent daily to obtain fuel?

Биодизельное

Этанол из кукурузы

Битуминозные пески

Этанол из сахарного тростника

Горючие сланцы *

Фотоэлектричество

Поиск нефтяных месторождений

Природный газ, 2005 г.

Импорт нефти, 2007 г.

Нефть и газ, 2005 г.

Импорт нефти, 2005 г.

Ветер

Производство нефти

Нефть и газ, 1970 г.

Импорт нефти, 1990 г.

Уголь

* EROI горючих сланцев (35…40% керогена), за счет подземной конверсии по технологии Кванттор, можно поднять до 25…30 единиц.

- 80.0Coal mining

- 35.0Oil, import volume in 1990

- 30.0Oil & gas, extraction volume in 1970

- 20.0Oil production

- 18.0Wind

- 18.0Oil, import, volume in 2005

- 14.0Oil & gas, extraction volume in 2005

- 12.0Oil, import volume in 2007

- 10.0Natural gas, extraction volume in 2005

- 6.8Photoelectricity

- 5.0Oil shale*

- 5.0Sugar-cane ethanol

- 3.0Bituminous sands

- 1.3Corn ethanol

- 1.3Biodiesel fuel

energy gained

expended

If for some resources the EROEI index is less or equals to 1, such a resource then becomes “energy devourer” and can’t be used as a primary energy source.

* EROI index for oil shale (35...40% kerogene) may be increased for 25...30 units due underground conversion based on Quanttor technology.

“Developed, tested, implemented”... as in nature.

Tornado is a like a heat engine where heat energy contained in natural air is converted into kinetic energy of air.

Vortex is the basic operating mechanism of Quanttor technology.

Phenomenal properties

Direct conversion of chemical energy into kinetic energy. Efficient output — up to 70%

The lowest CO, CH & NOx emission levels — up to 2 ppm-almost complete absence of carbon char.

Efficiently utilizes fuel- with any BTU content.

“Gas turbine combustion engine

developed by Anatoliy Rakhmailov

opens up a new era for

efficient and eco-friendly engines.”

Honorary Professor, Chair, Mechanical Engineering Department, Denver University, Colorado, US.

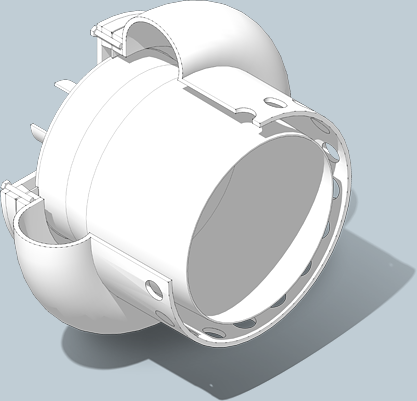

Quanttor Reactor

Simple, reliable, technology-savvy.

«Scientific history proves that [innovative] individuals had been more correct in their assertions that entire corporations of scientists or hundreds and thousands of orthodox researchers.»

Quanttor reactor is a conversion appliance of hydrocarbon fuel to hydrogen and carbon monoxide.

Quanttor reactor is an appliance for converting chemical energy of hydrocarbon fuel directly into kinetic energy resulting from chemical reactions of fuel with an oxidizing agent.

Prospective scopes of application

- TRANSPORTATION

- AERONAUTICS & ASTRONAUTICS

- DRILLING PLATFORMS

- POWER PLANTS

- FIRE PROTECTION

- GAS LASERS

- HOUSEHOLD WASTE DUMPS

Conversion of any hydrocarbon fuel to hydrogen and carbon monoxide with utilization of that «novel fuel» in reciprocator’s combustion chamber provides: improvement of dynamics, economics, and environmental pattern of transportation facilities.

The major weakness of hydrocarbon fuel is its low typical combustion rate manifesting itself as misfire of fuel compound within ICE combustion chamber. It is explained by its unstable spontaneous ignition — especially in those modes characteristic of low revolution rates and low loads. This weakness could be easily remedied by using hydrogen as ICE fuel, due to its unique physical and chemical properties.

Another aspect of

Converting automotive fuel to hydrogen

Enables transition to isothermal expansion of fuel conversion products in turbines of

Preliminary conversion of hydrocarbon fuel to H2 and CO within Quanttor reactor provides new opportunities for supersonic engines. Aircrafts in XXI century fly with hypersonic speed. It is achievable by specific engine design. There are no rotating parts in hypersonic propulsive jet; and the aircraft fitted with such an engine is capable of covering a distance of hundred kilometers in few seconds as well as going into a

Combined propulsive jet for

Develops

Quanttor technology application enabled arrangement of reliable and

A significant advantage of Quanttor reactor is its ability to utilize untreated associated petroleum gas with variable composition, calorie power values, and hydrogen sulfide content up to 5%. Structural features of reactor and application of special

Obtaining «novel fuel» from associated petroleum gas

For thermal power plants that currently utilize coal — Quanttor technology provides for mandatory

According to data provided by Energy Economy Research Institute of UES of Russia, share of natural gas in energy production in Russia in 2006 corresponded to 51%, and coal was 18%. Meanwhile, USA produce 52% of energy based on coal, Germany — 54%, China — 72%, and Poland — 94%. With the depletion of main

However, coal energy engineering is closely related to pressing and virtually insoluble environmental problems; besides, human losses are often associated with coal extraction and transportation processes. Problems emerge at coal extraction sites because coal is lifted from the depth to the surface. Where coal is burnt- problems are even greater. Can we avoid the above disasters of coal energy engineering? We can — by means of preliminary coal conversion including underground conversion using QUANTTOR technology.

Quanttor technology enables viewing fires and explosions (mainly referred to lean

One of detonative explosion prevention methods is desensitization of

Inert gas production technology for fire extinguishing purposes

Chemical agents mixing technology provides for significant reduction of time to mix chemical agents in gas lasers. It enables improvement of laser specifications — e.g. increasing their specific capacitance while decreasing cost of production.

Development of laser

Cooling system for Quanttor reactor is adaptable for

Implementation of proprietary chemical agents mixing system for gas lasers enables elimination of another bottleneck in the way of expanding capacities of gas lasers — chemical agents mixing with the use of

Military

Obtain heat and kinetic energy from

The pit is fitted with engineering facilities for leadaway of liquid and gaseous waste decomposition products and pumping equipment is installed. Extracted gas is transferred via pipelines to power stations to turbine generators, to

In the first 2…3 months of

Producing electric and heat energy from LFG

Business Contacts History

Longstanding cooperation with highly skilled specialists from various

Design of aircraft 2500 kW GTE

USSR Ministry of Defense

Design of automotive hybrid 50 kW GTE Design of Quanttor reactor for converting coal to hydrogen and carbon monoxide.

Департамент энергетики США

Design of 1500 kW GTE for compressor drives.

«Газпром»

Design of Quanttor reactor for converting crude oil to hydrogen and carbon monoxide for GTEs with a capacity up to 10 MW.

Saudi Electricity Company (SEC)

Design of Quanttor reactor for converting diesel fuel to hydrogen and carbon monoxide for 100 kW diesel engines.

RR

Design of Quanttor reactor for automotive ICE 75 kW.

Ford Motor Company

Design of automotive hybrid 62 kW GTE.

Volkswagen AG

Design of Quanttor reactor for 1300 kW GTE.

Kawasaki Heavy Industries, Ltd

Design of Quanttor reactor for aircraft 1000 kW GTE.

Honeywell

Design of 62 kW aircraft auxiliary power unit.

Solar Turbines

Design of Quanttor reactor for 10 MW GTE.

GE

Design of Quanttor reactor for industrial 1000 kW GTE.

Allison Engine Company (дочернее предприятие RR)

Design of Quanttor reactor for 60 MW GTE.

DYNEGY Inc.

Design of automotive hybrid 100 kW GTE.

GM

Developing design for a demonstrator model based on aircraft

Корпорация «Ивченко-Прогресс»

Manufacturing of a demonstrator model based on aircraft

АО «Мотор-Сич»